We call it… The £77,000 Paradox

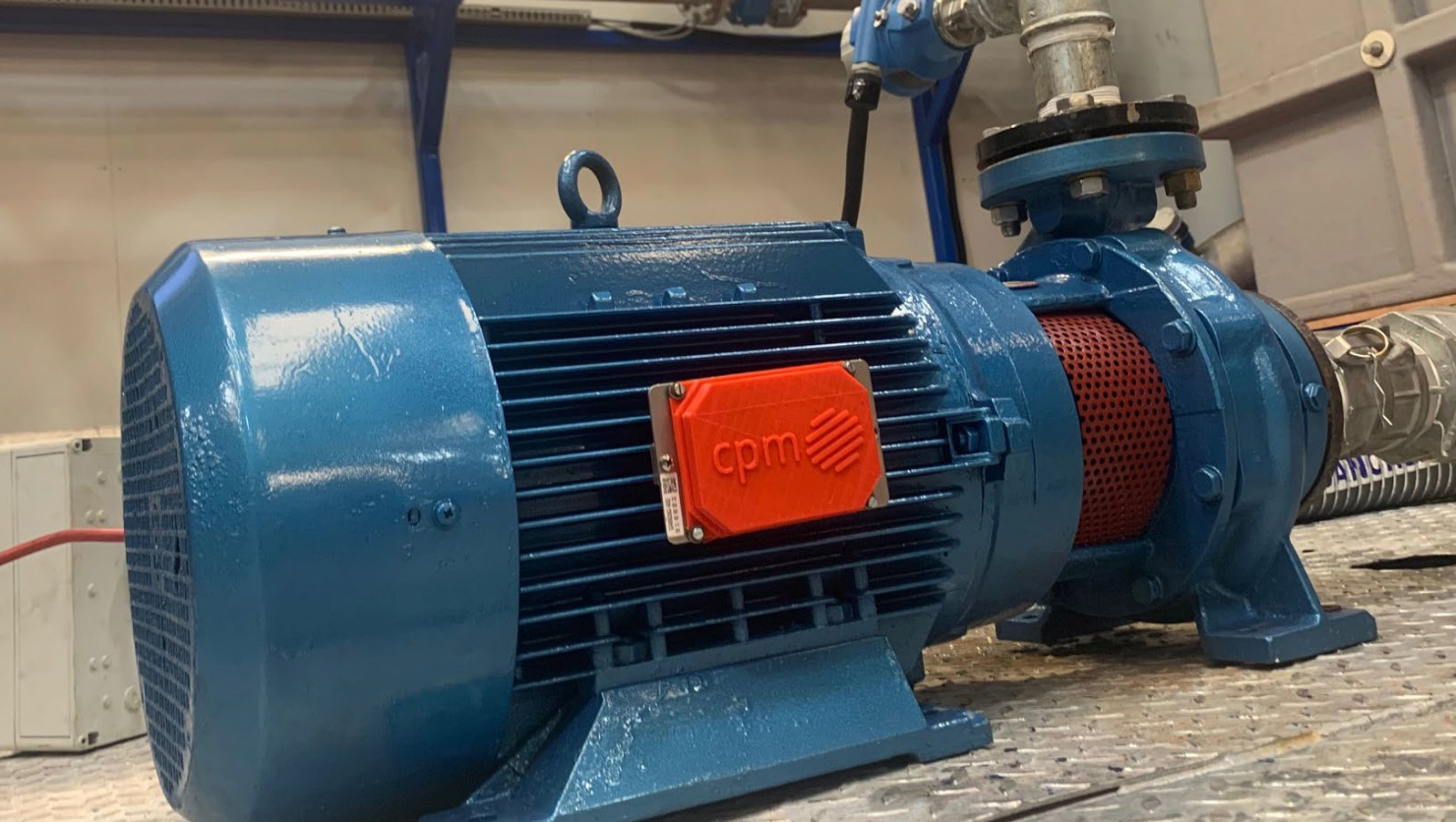

The new ‘fitbit’ for rotating machinery that takes nearly no time to install, but makes BIG savings for our customers.

Why would a business that specialises in the repair of rotating electrical and mechanical machinery, NOT want to repair rotating electrical and mechanical machinery?

With 33 years of experience, £3m workshop (one of UK’s largest), a 15 tonne lifting facility and expert engineers, you’d think that at CPM, we’d want even more repair work. Not less.

How does that work?

Surely it doesn’t make sense.

Why would a business that specialises in the repair of rotating electrical and mechanical machinery, NOT want to repair rotating electrical and mechanical machinery?

But it does make sense.

It makes perfect sense for us.

And it makes perfect sense for you too. Because the less time we spend repairing failed machinery – the more time it’s working to make you money.

And the more you make, the more clearly you can appreciate the many cost and time saving benefits of our new smart monitoring systems.

The high value shift from expensive repair work to preventative maintenance and smarter, safer resource management using new smart monitors.

Cost savings, time savings, energy efficiencies, improved safety, reliability and motor life that we now deliver UK-wide.

Smart monitoring that:

Saved £77,000 over a three year period, in downtime, repair and energy costs.

Slashed downtime and overhauling costs on a single rotating machine by £17,000 in just 3 months!

Delivered a major European manufacturer annual energy savings of more than 10% per motor and a 15% saving in maintenance team costs across their entire production.

Smart monitoring because…

and there’s no surprise here…

Prevention is better than cure

What is surprising is that only 25% of businesses use ‘systematic condition monitoring’ to cut costs, save time and radically increase the lifespan (and value) of their rotating machines.

But now, Smart Sensors do it for you. Motors driving everything from pumps, gearboxes, conveyors and compressors to HVACs and fans.

And it’s especially surprising because setting up your monitors is quick, it’s easy and it’s FREE.

That’s right. Our ‘proof of concept smart monitor trial’ means we’ll fit your new smart monitors absolutely free.

The Numbers Quickly Add Up

How many motors do you run?

20? 200? 800? 8000?

Did you know that planning maintenance reduces downtime by a third?

And that planned maintenance is a third the cost of repairing failed machines?

Imagine how much money you could save?

Even if you only focused on your ‘showstoppers’ – your most productive, most-expensive-to-repair machines.

The numbers quickly add up. To some very big numbers indeed. As skilled, experienced experts in Smart Monitor RCM (Remote Condition Monitoring) analysis and rotating machine service and repair, we’re perfectly placed to make sure you get those numbers.

In fact we back ourselves to achieve that. We’ve many sites where we commit to take on all repair costs (whatever the cost) for a fixed annual fee.

The Smartest Smart

Sensors In The World

At CPM we only work with the best. So we went out to the market and we found the best.

ABB Smart Sensors.

We’re proud to say that we’re now an authorised Digital Partner.

ABB Digital Partner Status

As an ABB Digital Partner we’re perfectly placed to advise and support you on specialist ABB applications, solutions, services and products.

All the ABB tools and resources, including product updates, service notes and new products you need to keep you working productively and profitably.

An CPM/ABB partnership that guarantees sustainable efficiencies and performance benefits.

The ABB Advantage

While manual ‘route based’ condition monitoring typically only measure vibrations and temperature, the ABB Ability Smart Sensor measures much more, including vibrations, magnetic field, temperature, energy efficiency and acoustics.

- More accurate than other smart sensors

- Battery life up to three times longer than most competing designs

- Comprehensive cybersecurity features to protect your data

How Smart Sensors Work For You

We attach your tough, lightweight and low cost ABB monitoring sensors to your motors and collect real time stress data including:

- Power

- Alignment

- Vibration

- Speed

- Skin temperature

This raw data is securely transmitted to a cloud-based server and analysed using advanced algorithms. Performance results are analysed by CPM triage specialists and advice shared via a smartphone app with your maintenance teams who can quickly handle any issues. Engineers can review the analysis on the Smart Sensor Portal and use the information to identify performance improvements, schedule work and spot energy saving opportunities.

No more time spent gathering data and reporting on each motor. No more guesswork. No more unplanned downtime.

- Reduce downtime by 70%

- Expand a motors life by 30%

- Improve energy efficiency by 10%

The more data you collect – the more accurate your MTBF (Mean Time Between Failures) and the larger the savings over the long term.

COVID-19 Secure

With restricted plant access due to social distancing and risk assessment protocols, Smart Monitoring is a simple and safe way to keep a close and constant eye on the health of your rotating machinery. Without risking the health of your staff.

Health & Safety

With no need to access rotating machinery and remove guards Smart Monitoring also reduces the possibility of accidents.

Choose The Smart Monitoring Support

That’s Right For You

Level 1 – Smart Sensor supply, installation and training. You manage and interpret the data.

Level 2 – Smart Sensor supply, installation, training and integration. Sensor management through digital model or Supervisory Control and Data Acquisition (SCADA). We receive and interpret the data and contact you to diagnose any issues and agree on a rectification plan.

When we talked about the £77,000 Paradox earlier we were talking about our Level 3 Package.

Level 3 includes the supply and installation of your ABB Smart Sensors plus your team training. We also remotely manage and interpret the data through your digital model.

But this is where it gets interesting (and hugely financially beneficial). Because this is a fixed fee maintenance package.

We’ll agree to a term and a rate that delivers you a significant annual saving.

We’ll then GUARANTEE all motor and maintenance over that period at our own risk.

You save money, enjoy predictable repair and maintenance costs, and work safe in the knowledge that your motors are secured.

We work 24/7 using our ABB Smart Sensor technology to make sure repair and maintenance costs are minimised.

We’re backing ourselves. We’re backing our technology.

All you have to do is save the cost, time and inconvenience of motor failure.

Secure Your Motors and Your Budgets

Time to learn more about how CPM Smart Sensors can radically reduce the cost and inconvenience of your motor failures?

Contact Rishi Hirani at rhirani@cpm-uk.com

Find out about our ‘Pay as you go’ options and FREE Smart Sensor ‘proof of concept’ trials.

And don’t forget to ask about how we save customers tens of thousands of pounds every year with our fixed fee maintenance packages.

That’s right. We’re so confident in our Smart Sensor cost savings we’ll GUARANTEE all motor and maintenance – all at our own risk.